BUTTE, MT – Resodyn Corporation and its associated companies, Resodyn Acoustic Mixers and Resodyn Engineered Polymeric Systems, continued their growth in 2018, driving an expanded headcount with robust and diverse talents. New staff members include process engineers, sales engineers, and marketers to better serve a growing global customer base. Additional product engineers, operations specialists, and manufacturing technicians continue the expansion of Resodyn’s U.S. based design, manufacturing, and global logistics operations.

Despite all the recent hiring , Resodyn is aiming to further grow its team with positions open in a number of disciplines.

“To put it simply, customer demand for our world-class solutions is strong.” said Resodyn’s CEO Larry Farrar. “Our consistent growth is a result of continuous development and improvement, integrating our customers’ requirements, and delivering processing solutions of exceptional quality and performance. Resodyn’s products are driving fundamental change in numerous industries by energizing product quality and new product development.”

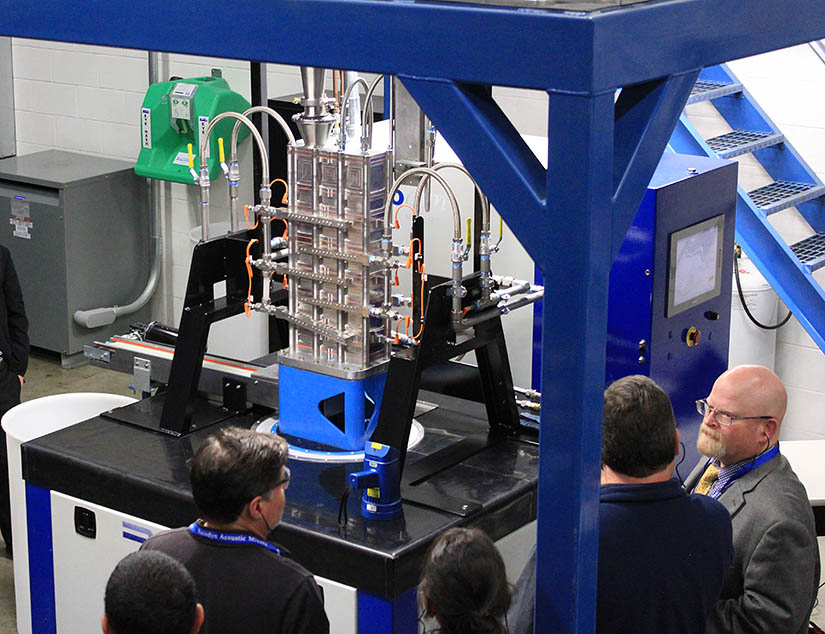

RAM 5 Mixers being tested before shipment.

Resodyn Continuous Acoustic Mixing (CAM) Demonstration on RAM 5

Resodyn is best known for its innovative line of industrial processing and mixing products. The company’s patented ResonantAcoustic® Mixing (RAM) technology enables high-speed and high-quality processing of liquids, powders, pastes, and highly viscous materials at scales from the benchtop LabRAM Mixers for laboratory development to production scale systems. RAM Mixers are prevalent in energetics, pharmaceutical development and manufacturing, advanced materials, battery and energy storage development, and dozens of other industries.

Notable recent projects include the manufacture of a Continuous RAM 5 H energetics mixer for the US Navy, a large-scale RAM 55 H mixer for the US Army, and development of Continuous Acoustic Reactor technology, driven by strong interest across a broad spectrum of industries. The company is engaged in numerous other development contracts with private companies in industries from pharmaceuticals to batteries.

Resodyn Engineered Polymeric Systems (REPS) is also garnering attention, having recently won several competitive development projects. Under two Small Business Innovation Research (SBIR) grants, the company has developed and is now demonstrating durable and easily repaired coatings for the hulls of US Navy vessels multiplying mission readiness. A second project in later stage testing involves leading-edge protection for wind turbine blades, increasing service life and extending high efficiency kWh production.

A current U.S. Navy project recently completed testing the effectiveness of an intumescent (heat insulating/resistant) coating of Navy munitions. Early test results exceed traditional fire and heat protection coating systems. All REPS coatings are applied with Resodyn’s patented Polymer Thermal Spray (PTS) systems, enabling field application and repair of thermoplastic and thermoset coatings.

Collectively, the Resodyn companies boast an impressive list of clients from US federal agencies like the DOE, DARPA, and FBI, to multiple arms of the DOD including the Army, Navy, Air Force, and Missile Defense Agency, to numerous top tier corporations in industries from Pharmaceuticals to nano-materials.

“We wouldn’t be here if it wasn’t for our customers. That sounds cliché, but Resodyn’s customers tend to be a special breed. They are visionary, challenging, and open-minded. These customers pursue new and better ways of growing their businesses and partner with companies like Resodyn to help them achieve their objectives.”

To learn more about Resodyn Acoustic Mixers, visit ResodynMixers.com.

For information about about Resodyn Engineering Polymeric Systems, visit ResodynCoatings.com.

To see all Resodyn job opportunities, visit Resodyn.com/careers.